Thermal Conductivity

Direct measurement of thermal conductivity can be complex and difficult, especially in small samples.

We determine the thermal conductivity of materials by measuring thermal diffusivity and calculating using the equation below:

α=K/(ρCP )

Where a is the thermal diffusivity

•K is thermal conductivity

•r is density

•Cp is the specific heat (at constant pressure).

Note that conversion from thermal diffusivity to thermal conductivity requires the correction of room temperature density data for thermal expansion.

The relative ease with which it is possible to measure thermal diffusivity, makes it a useful tool for the determination of a material’s thermal conductivity.

Composite Mediums

Not only can the laser flash technique be used to measure the bulk properties of the a material it can be used to measure the thermal conductivity of a single layer in a composite medium.

At Wood, bespoke software has been produced to analyse the laser flash diffusivity measurement data and determine the thermal conductivity of a layer or coating in a composite sample, which may be different to the bulk thermal conductivity for that material. For example, paint ceramic coatings on turbine blades (0.1mm to 3.0mm thick) or polymer paint coatings on steel substrates (<200µm thick).

Thermal Diffusivity

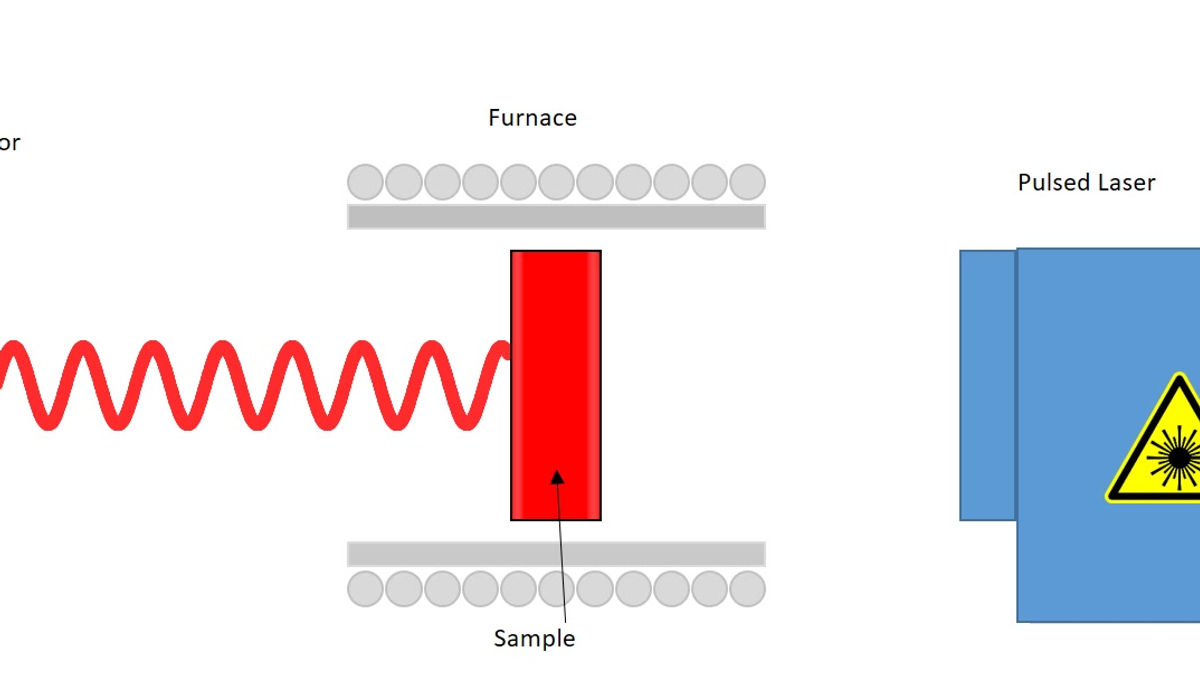

At Wood Thermal, thermal diffusivity is measured using the laser flash technique, in accordance with ASTM standards.

The laser flash technique determines the thermal diffusivity, by rapidly heating one side of a small thin sample using a laser beam and recording the temperature change on the other side of the sample.

The time taken for the heat energy to diffuse through the sample can be related to the material thermal diffusivity using the equation below:

α=ω/π^2 L^2/t^½

Where

•a = thermal diffusivity

•L = thickness of the sample

•w = a constant, dependent on the heat loss from the system

•t½ = the time taken for the rear face of the sample to reach half the maximum change in temperature

All testing is performed in a vacuum chamber with the sample mounted inside a furnace, which is used to heat the sample to a prescribe temperature before a laser flash measurement is made, to allow temperature vs thermal conductivity characterisation and identification of phase transitions.

The furnace in Wood’s system can operate between Room temperature and up to 2000°C.